What Is a Maintenance Work Order?

A maintenance work order is a formal document that authorizes and details maintenance or repair tasks. It acts as a central hub for information, facilitating task management, resource allocation, and historical tracking of maintenance activities. When a maintenance issue arises, a work order is created to ensure that the necessary steps are taken to address the problem promptly and effectively.

These documents provide a clear roadmap for maintenance technicians, outlining the specific tasks to be performed, materials needed, safety precautions, and any other relevant information. By formalizing the maintenance process through work orders, organizations can streamline their maintenance operations, improve efficiency, and ensure the proper functioning of facilities and equipment.

Maintenance Work Order Types

Preventive Maintenance Work Orders

Preventive maintenance work orders are scheduled in advance to perform routine maintenance tasks on equipment or facilities. These tasks are designed to prevent equipment breakdowns, reduce the risk of failures, and prolong the lifespan of equipment. Preventive maintenance work orders typically include tasks such as inspections, lubrication, adjustments, and replacements of worn parts. By scheduling preventive maintenance tasks through work orders, organizations can proactively address potential issues before they escalate into costly repairs or downtime. Preventive maintenance work orders are essential for maintaining the reliability, efficiency, and safety of facilities and equipment.

Corrective Maintenance Work Orders

Corrective maintenance work orders are created in response to unexpected equipment failures or issues that need immediate attention. These work orders are used to address problems that have already occurred, such as malfunctions, breakdowns, or defects. Corrective maintenance work orders typically involve troubleshooting the issue, identifying the root cause, and implementing repairs or replacements as needed. By creating corrective maintenance work orders, organizations can respond quickly to equipment failures, minimize downtime, and restore operations to normalcy. Corrective maintenance work orders are essential for addressing unexpected issues and ensuring the reliability and performance of facilities and equipment.

Emergency Maintenance Work Orders

Emergency maintenance work orders are created for urgent maintenance tasks that require immediate action to prevent safety hazards or further damage. These work orders are used in situations where there is an imminent risk to personnel, property, or operations. Emergency maintenance work orders typically involve critical repairs, shutdowns, or interventions to address urgent issues. By prioritizing emergency maintenance tasks through work orders, organizations can respond promptly to emergencies, minimize risks, and ensure the safety and continuity of operations. Emergency maintenance work orders are essential for addressing high-priority issues and maintaining a safe and functional work environment.

Maintenance Work Order Process Flow

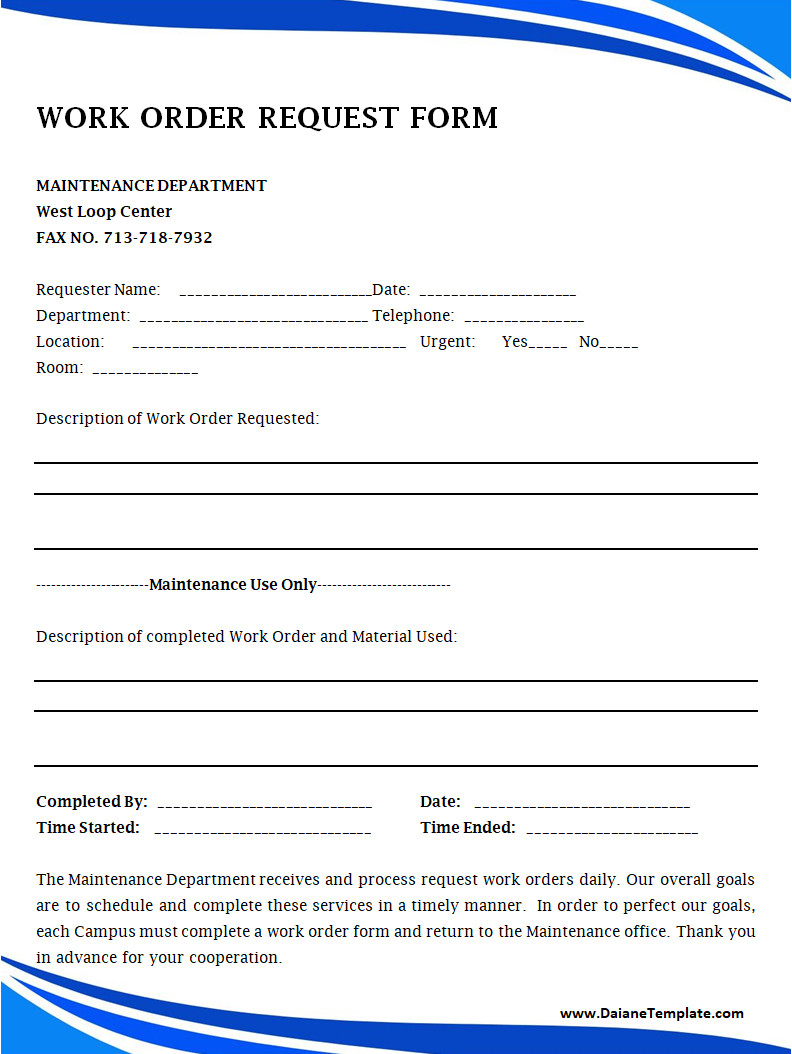

Work Order Request

The maintenance work order process typically begins with a work order request submitted by a user or technician. The request may be initiated through a work order system, maintenance management software, or directly to the maintenance department. The work order request should include details such as the location of the issue, description of the problem, urgency, and any other relevant information. By capturing this information in the work order request, organizations can ensure that maintenance tasks are prioritized, assigned, and completed on time. The work order request serves as the starting point for the maintenance work order process and provides essential information for initiating the maintenance task.

Work Order Creation

Once the work order request is received, the maintenance supervisor or manager creates a work order based on the information provided. The work order should include details such as the description of the issue, materials needed, estimated time for completion, safety precautions, and any special instructions. By creating a detailed work order, organizations can ensure that maintenance tasks are communicated effectively to maintenance technicians and other stakeholders involved in the process. The work order serves as a roadmap for the maintenance task, outlining the specific steps to be taken, resources required, and expected outcomes. The creation of the work order is a critical step in the maintenance work order process, as it sets the foundation for the successful completion of the maintenance task.

Work Order Assignment

Once the work order is created, it is assigned to a maintenance technician or team responsible for completing the task. The work order assignment should be based on factors such as technician availability, expertise, and workload. By assigning the work order to the right individual or team, organizations can ensure that the maintenance task is completed efficiently and effectively. The assigned technician should review the work order, understand the scope of work, gather the necessary materials and tools, and prepare to carry out the maintenance task. The work order assignment is a critical step in the maintenance work order process, as it determines who will be responsible for executing the task and ensures that the necessary resources are allocated to complete the maintenance activity.

Work Order Execution

Once the work order is assigned, the maintenance technician carries out the maintenance task according to the instructions provided in the work order. The technician follows the steps outlined in the work order, uses the materials and tools specified, and adheres to any safety precautions or procedures. During the execution of the work order, the technician may encounter unforeseen challenges, unexpected issues, or additional tasks that need to be addressed. In such cases, the technician should communicate any deviations from the original work order to the supervisor or manager for guidance and approval. The successful execution of the work order is essential for completing the maintenance task effectively and ensuring the safe and efficient operation of facilities and equipment.

Work Order Completion

After completing the maintenance task, the technician updates the work order with relevant information, such as the work performed, materials used, time taken, and any issues encountered. The technician may also provide recommendations for future maintenance activities or repairs that may be needed. Once the work order is updated, it is reviewed by the maintenance supervisor or manager to ensure that the task was completed satisfactorily and that all necessary information is documented. The work order is then closed in the system, marking the official completion of the maintenance task. Work order completion is a critical step in the maintenance work order process, as it signifies that the maintenance activity has been successfully carried out and documented for reference and tracking purposes.

Work Order Review

After the completion of the maintenance task, the maintenance supervisor or manager reviews the work order to assess the quality of work performed, verify that all information is accurate and complete, and identify any follow-up actions that may be required. The work order review helps to ensure that maintenance tasks are carried out to the required standards, that any issues are addressed promptly, and that all necessary documentation is in place. During the review process, the supervisor may analyze the data collected in the work order, identify trends or patterns, and make recommendations for improvements in maintenance operations. The work order review is an essential step in the maintenance work order process, as it provides an opportunity to evaluate performance, identify areas for enhancement, and drive continuous improvement in maintenance activities.

Key Components of Maintenance Work Orders

Work Order Number

A work order number is a unique identifier assigned to each work order for tracking and reference purposes. The work order number helps to distinguish one work order from another, providing a clear identification of each maintenance task. By assigning a unique work order number, organizations can easily track the progress of maintenance activities, refer back to specific work orders for future reference, and maintain an organized record of maintenance history. The work order number serves as a key component of maintenance work orders, enabling efficient tracking, monitoring, and management of maintenance tasks.

Description of the Issue

A detailed description of the maintenance issue is a critical component of maintenance work orders. The description should provide specific information about the problem, including the location, equipment involved, nature of the issue, and any symptoms or observations. By documenting a detailed description of the issue in the work order, organizations can ensure that maintenance technicians have clear instructions on how to address the problem effectively. The description of the issue serves as a reference point for maintenance technicians, helping them to understand the scope of work, identify potential causes, and determine the appropriate course of action to resolve the issue.

Materials and Tools Required

A list of materials and tools required for the maintenance task is an essential component of maintenance work orders. The list should include all the necessary materials, parts, tools, and equipment needed to complete the maintenance activity. By specifying the materials and tools in the work order, organizations can ensure that maintenance technicians have access to the resources they need to perform the task efficiently and effectively. The materials and tools required component helps to streamline the maintenance process, prevent delays due to resource shortages, and ensure that the maintenance task is completed to the required standards.

Estimated Time for Completion

The estimated time for completion is a crucial component of maintenance work orders that helps to schedule resources, plan workflow, and prioritize tasks. The estimated time should provide an indication of how long it will take to complete the maintenance task, based on factors such as the complexity of the issue, availability of resources, and technician expertise. By including an estimated time for completion in the work order, organizations can manage their maintenance schedule, allocate resources efficiently, and set expectations for when the task is expected to be finished. The estimated time for completion component is essential for effective time management, task prioritization, and workload planning in maintenance operations.

Safety Precautions

Safety precautions are a critical component of maintenance work orders that help to ensure the safety of maintenance technicians, occupants, and facilities during maintenance activities. The safety precautions should include any special safety instructions, procedures, or precautions that need to be followed to prevent accidents, injuries, or damage. By highlighting safety precautions in the work order, organizations can promote a culture of safety, minimize risks, and comply with safety regulations and standards. The safety precautions component is essential for creating a safe working environment, protecting personnel from harm, and preventing incidents during maintenance tasks.

Best Practices for Managing Maintenance Work Orders

Implementing a Computerized Maintenance Management System (CMMS)

One of the best practices for managing maintenance work orders is to implement a computerized maintenance management system (CMMS). A CMMS is a software tool that helps organizations streamline their maintenance operations by centralizing work order creation, assignment, tracking, and reporting. By using a CMMS, organizations can automate repetitive tasks, standardize processes, improve communication, and enhance visibility into maintenance activities. A CMMS allows organizations to manage work orders more efficiently, track maintenance history, analyze performance metrics, and make data-driven decisions to optimize maintenance operations. Implementing a CMMS can improve productivity, reduce costs, and enhance overall maintenance performance.

Prioritizing Work Orders

Another best practice for managing maintenance work orders is to prioritize tasks based on urgency, safety concerns, and impact on operations. By prioritizing work orders effectively, organizations can ensure that critical maintenance tasks are addressed promptly, resources are allocated appropriately, and downtime is minimized. Prioritization helps to focus on high-priority tasks first, address safety-critical issues immediately, and optimize resource utilization. By establishing clear criteria for prioritizing work orders, organizations can enhance operational efficiency, reduce risks, and maintain the reliability of facilities and equipment.

Providing Clear and Detailed Instructions

Clear and detailed instructions are essential for managing maintenance work orders effectively. Work orders should provide specific guidance on the scope of work, steps to be taken, materials and tools required, safety precautions, and any other relevant information. By providing clear and detailed instructions in work orders, organizations can ensure that maintenance technicians understand what needs to be done, how to do it, and any special considerations to be aware of. Clear instructions help to prevent misunderstandings, errors, and rework, leading to more efficient and accurate completion of maintenance tasks. Providing detailed instructions in work orders is essential for standardizing processes, improving communication, and ensuring that tasks are performed to the required standards.

Communicating Regularly with Maintenance Technicians

Effective communication with maintenance technicians is key to managing maintenance work orders successfully. Regular communication helps to provide updates on work orders, clarify instructions, address any issues or concerns, and ensure that tasks are progressing as planned. By maintaining open lines of communication with maintenance technicians, organizations can foster collaboration, build trust, and enhance teamwork in maintenance operations. Communication helps to keep all stakeholders informed, aligned, and engaged in the maintenance process, leading to better outcomes and increased efficiency. Regular communication with maintenance technicians is essential for coordinating activities, resolving issues, and ensuring that maintenance tasks are completed on time and to the required standards.

Conducting Regular Reviews of Completed Work Orders

Regular reviews of completed work orders are essential for managing maintenance activities effectively. By reviewing work orders, organizations can assess the quality of work performed, identify trends, patterns, and areas for improvement, and make data-driven decisions to enhance maintenance performance. Work order reviews help to evaluate the effectiveness of maintenance processes, track key performance indicators, and identify opportunities for optimization. By analyzing completed work orders, organizations can identify recurring issues, root causes of problems, and areas where efficiency can be improved. Regular reviews of completed work orders are essential for continuous improvement, performance evaluation, and enhancing overall maintenance operations.

Training Maintenance Staff on Work Order Systems

Training maintenance staff on how to use work order systems effectively is crucial for managing maintenance work orders. By providing training on work order systems, organizations can ensure that maintenance technicians understand how to create, update, assign, and complete work orders accurately. Training helps to familiarize staff with the features and functionalities of work order systems, optimize their use, and maximize the benefits of using technology to manage maintenance operations. By equipping maintenance staff with the necessary skills and knowledge to navigate work order systems, organizations can enhance efficiency, accuracy, and effectiveness in managing maintenance work orders. Training on work order systems is essential for empowering staff, improving adoption rates, and driving successful implementation of maintenance processes.

Maintenance Work Order Template

Maintenance Work Order Template – WORD