In the world of manufacturing, the production schedule plays a crucial role in ensuring that operations run smoothly and efficiently. By coordinating the sequence of tasks and allocating resources like materials, labor, and equipment, businesses can meet customer demand promptly while minimizing costs and waste.

A well-planned production schedule helps to avoid delays and bottlenecks, maximize resource utilization, and ensure on-time delivery of products. Let’s delve deeper into why production scheduling is essential for optimizing manufacturing processes.

What is a Production Schedule?

A production schedule is a detailed plan that outlines the sequence of tasks, resources, and timelines required to produce goods or services. It serves as a roadmap for manufacturing operations, guiding the allocation of resources and ensuring that production runs smoothly from start to finish.

By creating a production schedule, businesses can optimize their processes, streamline operations, and improve efficiency.

Why the Production Schedule is Important in Manufacturing?

Efficient Resource Management

One of the primary reasons why production scheduling is important in manufacturing is efficient resource management. By creating a production schedule that outlines the resources required for each task, businesses can ensure that materials, labor, and equipment are utilized effectively. This not only helps minimize waste and reduce costs but also maximizes resource utilization, leading to increased efficiency and productivity in the production process.

Timely Delivery

Meeting customer demand on time is crucial for maintaining customer satisfaction and loyalty. A production schedule plays a vital role in ensuring on-time delivery of products by setting realistic timelines for each task and monitoring progress to prevent delays. By following a well-planned production schedule, businesses can streamline their operations, avoid bottlenecks, and ensure that products are delivered to customers when they are needed.

Cost Reduction

Effective production scheduling can help businesses minimize costs associated with idle time, overtime, and inefficient resource utilization. By creating a detailed plan that optimizes the use of resources and streamlines production processes, organizations can reduce operational expenses and improve profitability. A well-executed production schedule ensures that resources are allocated wisely, tasks are completed efficiently, and costs are kept under control, leading to overall cost reduction in manufacturing operations.

Improved Efficiency

Efficiency is a key driver of success in manufacturing, and a production schedule plays a crucial role in improving efficiency across all aspects of production. By carefully planning the sequence of tasks, optimizing resource allocation, and setting realistic timelines, businesses can streamline their operations, eliminate inefficiencies, and increase productivity. An effective production schedule ensures that operations run smoothly, tasks are completed on time, and resources are utilized effectively, leading to improved efficiency in manufacturing processes.

Enhanced Product Quality

Quality control is essential in manufacturing to ensure that products meet the required standards and specifications. A production schedule can help enhance product quality by enabling businesses to allocate resources effectively, monitor production processes closely, and identify potential issues early on. By following a structured plan that outlines the sequence of tasks and quality checkpoints, organizations can maintain consistency in product quality, reduce defects, and meet customer expectations.

Adaptability to Changes

In today’s fast-paced business environment, manufacturing processes are subject to constant changes and disruptions. A production schedule provides businesses with the flexibility to adapt to unexpected events, such as equipment breakdowns, material shortages, or changes in customer demand. By having a well-planned production schedule in place, organizations can quickly adjust production timelines, reallocate resources, and address any issues that may arise, ensuring that operations continue to run smoothly and efficiently.

What to Include in a Production Schedule?

When creating a production schedule, it is important to consider several key elements to ensure its effectiveness.

Sequence of Tasks

The sequence of tasks in a production schedule is critical for maintaining a smooth flow of operations. By defining the order in which tasks need to be completed, businesses can ensure that production processes are carried out efficiently and effectively. The sequence of tasks should take into account dependencies between different activities, resource availability, and any constraints that may impact the production process. By outlining the sequence of tasks in the production schedule, organizations can streamline their operations and improve overall efficiency.

Resource Allocation

Resource allocation is another key component of a production schedule that plays a crucial role in optimizing manufacturing processes. Businesses need to determine the resources required for each task, including materials, labor, equipment, and any other resources needed to complete production activities. By allocating resources effectively based on the production schedule, organizations can minimize waste, reduce costs, and maximize resource utilization. Effective resource allocation ensures that the right resources are available at the right time, allowing production processes to run smoothly and efficiently.

Timelines

Setting realistic timelines for each task is essential for ensuring that production stays on track and meets deadlines. Timelines in the production schedule should be carefully planned to account for the time required to complete each task, any dependencies between tasks, and any factors that may impact production timelines. By setting achievable timelines and monitoring progress against these timelines, businesses can ensure that production processes are completed on time and that products are delivered to customers as scheduled. Timelines play a critical role in maintaining efficiency, reducing delays, and meeting customer demand effectively.

Contingency Plans

Despite careful planning, unexpected events or disruptions can occur during the production process. Businesses need to have contingency plans in place to address any issues that may arise and prevent production delays. Contingency plans should outline alternative courses of action that can be taken in case of equipment breakdowns, material shortages, or other unforeseen circumstances. By anticipating potential challenges and having contingency plans in place, organizations can mitigate risks, minimize disruptions, and ensure that production continues to run smoothly even in the face of unexpected events.

How to Create an Effective Production Schedule

Creating an effective production schedule requires careful planning and coordination. Here are some steps to help you develop a successful production schedule.

Assess Your Capacity

Before creating a production schedule, it is important to assess your production capacity and limitations. Understanding the capabilities of your manufacturing operations will help you create a realistic and achievable schedule that aligns with your resources and capabilities. By evaluating your capacity, you can ensure that the production schedule is feasible and that tasks can be completed within the available resources and timelines.

Identify Critical Tasks

Identifying critical tasks that have the most impact on production timelines is essential for creating an effective production schedule. By prioritizing these tasks and ensuring they are completed first, businesses can prevent delays in the production process and maintain efficiency. Critical tasks may include activities that have dependencies on other tasks, tasks that require specialized resources or skills, or tasks that have a significant impact on overall production timelines. By focusing on critical tasks, organizations can optimize their production schedules and ensure that key activities are completed on time.

Allocate Resources Wisely

Resource allocation is a key aspect of creating an effective production schedule. It is important to allocate resources wisely based on the requirements of each task to ensure that materials, labor, and equipment are utilized efficiently. By carefully planning resource allocation in the production schedule, businesses can minimize waste, reduce costs, and maximize resource utilization. Effective resource allocation ensures that the right resources are available when needed, allowing production processes to run smoothly and efficiently.

Regularly Monitor and Adjust

Creating a production schedule is not a one-time task; it requires continuous monitoring and adjustment to ensure its effectiveness. It is important to regularly monitor the progress of production against the schedule, identify any deviations or delays, and make adjustments as needed to optimize efficiency. By monitoring production activities closely and making timely adjustments to the schedule, businesses can address issues

Communicate Effectively

Effective communication is essential for the successful implementation of a production schedule. It is important to keep all stakeholders informed about the production schedule, including employees, suppliers, and customers, to ensure that everyone is on the same page and working towards the same goals. Clear and open communication helps to prevent misunderstandings, address any issues that may arise, and maintain alignment between different departments and teams involved in the production process. By fostering effective communication, businesses can improve collaboration, coordination, and overall efficiency in manufacturing operations.

Use Production Planning Software

Investing in production planning software can streamline the scheduling process and improve accuracy in creating a production schedule. Production planning software offers advanced features such as scheduling tools, resource optimization, real-time monitoring, and reporting capabilities that can help businesses create detailed and optimized production schedules. By leveraging production planning software, organizations can automate scheduling tasks, reduce manual errors, and enhance overall efficiency in production planning and scheduling processes.

Implement Lean Manufacturing Principles

Lean manufacturing principles focus on eliminating waste, optimizing processes, and improving efficiency in production operations. By implementing lean manufacturing principles in production scheduling, businesses can identify and eliminate inefficiencies, reduce lead times, and improve overall productivity. Lean manufacturing emphasizes continuous improvement, employee involvement, and waste reduction, which can help businesses create a more efficient and effective production schedule that maximizes resource utilization and minimizes costs.

Collaborate with Suppliers

Collaborating closely with suppliers is essential for ensuring the timely delivery of materials and components needed for production. By maintaining strong relationships with suppliers, businesses can ensure a steady supply of materials, reduce lead times, and prevent production delays. Collaborating with suppliers also provides opportunities for cost savings, quality improvements, and innovation in the supply chain, which can have a positive impact on production scheduling and overall efficiency in manufacturing operations.

Train Employees

Training employees on the importance of following the production schedule and how it impacts overall efficiency is crucial for successful implementation. Employees play a key role in executing the production schedule and ensuring that tasks are completed on time and according to plan. By providing training on the production schedule, businesses can empower employees with the knowledge and skills needed to optimize production processes, improve productivity, and contribute to the success of the organization. Investing in employee training can lead to a more knowledgeable and engaged workforce that is committed to following the production schedule and achieving operational excellence.

Regularly Review and Improve

Continuous review and improvement of the production schedule are essential for optimizing efficiency and maximizing resource utilization. It is important to regularly review the production schedule, identify areas for improvement, and implement changes to enhance operational efficiency. By analyzing production data, monitoring performance metrics, and gathering feedback from stakeholders, businesses can identify opportunities for optimization, streamline processes, and improve overall effectiveness of the production schedule. Regular review and improvement ensure that the production schedule remains relevant, responsive to changing business needs, and aligned with organizational goals.

Optimize Production Schedule

Optimizing the production schedule is an ongoing process that requires strategic planning, coordination, and continuous improvement. By following best practices in production scheduling, businesses can streamline operations, reduce costs, and meet customer demand efficiently. A well-planned and executed production schedule is essential for maximizing resource utilization, minimizing waste, and ensuring on-time delivery of products. By focusing on efficiency, timeliness, and quality, organizations can achieve operational excellence and stay competitive in the dynamic manufacturing industry.

Future of Production Scheduling

As technology continues to advance and market demands evolve, the future of production scheduling is likely to be influenced by digital transformation, automation, and data analytics. Businesses are increasingly turning to advanced technologies such as artificial intelligence, machine learning, and predictive analytics to optimize production schedules, improve decision-making, and enhance operational efficiency. The integration of smart manufacturing systems, IoT devices, and cloud-based solutions is expected to revolutionize production scheduling by enabling real-time monitoring, predictive maintenance, and adaptive planning.

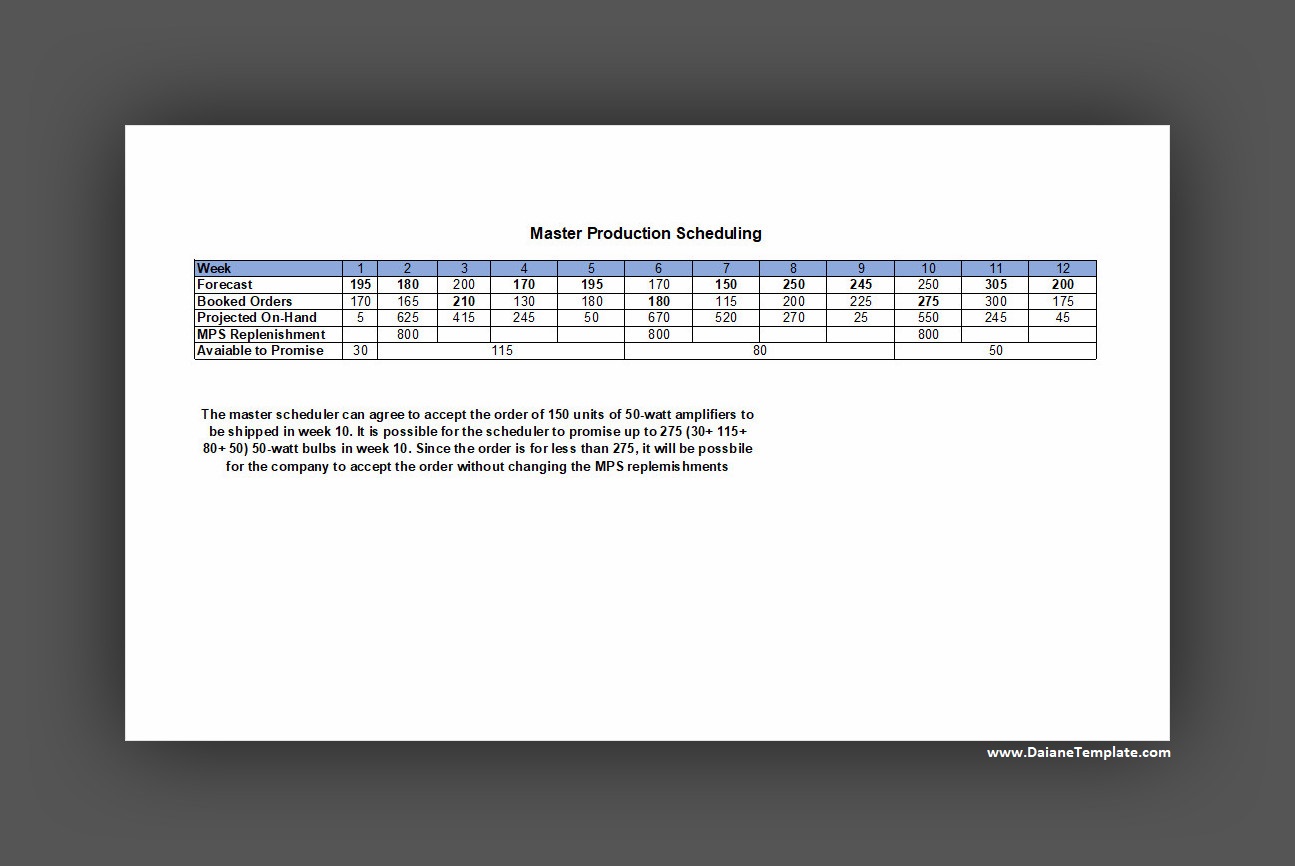

Free Production Schedule Template

In conclusion, a Production Schedule is an essential tool for planning, tracking, and managing production timelines efficiently. It helps allocate resources, prevent delays, and keep every project running smoothly.

Boost your productivity today—download our Production Schedule Template and take control of your production process!

Production Schedule Template – EXCEL